2500mm

40TDouble-Wire Fluting Paper Machine

This technical proposal is oriented to the

complete system of paper machine in the project of 2500mm fourdrinier wire multi-cylinder

paper machine. It accurately, clearly and completely describes the technical

requirements of users in the paper machine system, and gives the technical

program of the project so that our company and your company can discuss and

exchange technology

According to the requirements of the buyer,

based on the practical experience of the same type of paper machine that our

company has successfully completed, our company here clarify the technology and

supply scope of 2500/180 paper machine as follows:

This machine is used to 80-200g/m2 fluting

paper machine. It is composed of long web forming part, press part, drying part,

sizing machine part,calendar part,winding machine

part, transmission part, base plate part, hood part and so on.

Wire section adopts open-type head-box feed

pulp.The wire is 10083 mm long.

Pressure section made of 2 sets open-type pressure.(φ700/φ750)

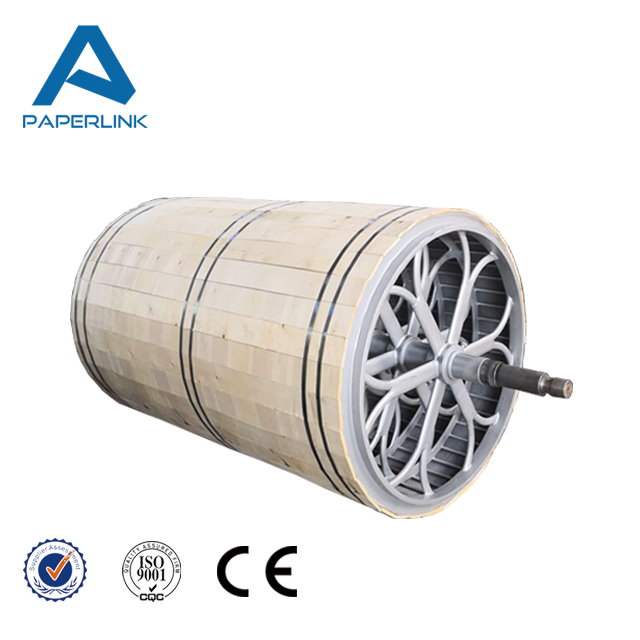

Drying section adopts 18 sets φ1500mm

cylinder dryers,The grouping arrangement is as follows:(6+6+sizing

machine+6).

paper winding section adopts horizontal pneumatic

cylinder rewinding machine.

The transmission section adopts segment

transmission and AC frequency conversion speed control

Technical Parameters

|

Output |

Fluting paper |

Trimmed width |

2500mm |

|

GSM |

80-200g/m2 |

Design speed |

180m/min |

|

Working speed |

130m/min |

Balance speed |

220m/min |

|

crawling speed |

25m/min |

Capacity |

40t/d |

|

Operation form |

Left(right)-hand

operation |

Roller

adjustment and balance requirements |

G1.6 |

|

Cylinder dryer

adjustment and balance requirements |

G2.5 |

Winding roll adjustment and balance requirements |

G1.6 |

|

Head-box feeding

pulp concentration |

0.3-0.8% |

Paper amplitude

shrinkage |

3%-4% |

|

Finished wire

part |

≥20-21% |

Finished press

part |

≥42-44% |

|

Finished drying

part |

≥92% |

layout types |

one Floor arrangement |

Paper machine

technological process

Open head-box → long wire section (wire length 10083mm) →

2 sets open-type press →12 setsφ1500mm

dryers→Sizing machine (φ550)→ 6 sets φ1500mm dryers→2-roller

calender →horizontal reel machine→Rewinder