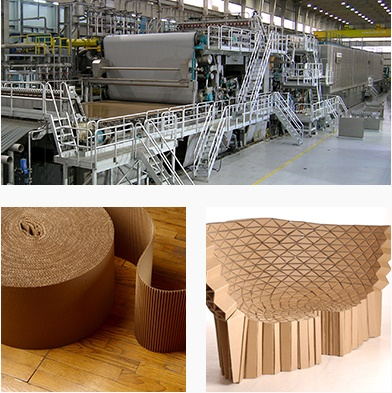

PACKAGING

CORE BOARD

This board is used for various applications where the quality of printing isn’t important. It is mainly used for producing tubes and spools for hygiene, battery and fabric paper industries. It is used for making consumer goods such as puzzles and games.

This board can create partitions for packaging, box dividers or slip-sheets.