3200mm 60T Fourdrinier Type A4 Paper Making Machine

This technical

proposal is oriented to the complete system of paper machine in the project of 3200mm

double-wire multi-cylinder paper machine. It accurately, clearly and completely

describes the technical requirements of users in the paper machine system, and

gives the technical program of the project so that our company and your company

can discuss and exchange technology

This machine is used to 80g/m2 A4 papermachine. It is composed of long web

forming part, press part, dry cadre, roll paper part, transmission part, base

part, hood part and so on.

Wire section

adopts wire forming, choose open-type head-box feed pulp.

Pressure section

made of 4 rollers with 2 press zones and 1 set large diameter rollers.

Drying section

adopts 18 sets φ1500mm cylinder dryers,The grouping

arrangement is as follows:(14+sizing

machine+8).

paper winding

section adopts horizontal pneumatic cylinder rewinding machine.

The transmission

section adopts segment transmission and AC frequency conversion speed control

Technical Parameters

|

Raw material |

virgin pulp |

Output |

A4 paper |

|

Trimmed width |

3200mm |

GSM |

80g/m2 |

|

Design speed |

250m/min |

Working speed |

180/min |

|

Transmission speed |

250m/min |

Capacity |

60T/D |

|

Gauge |

4300mm |

Transmissions type |

AC frequency division transmission |

|

Head-box feeding pulp concentration |

0.3-0.8% |

Winding roll balance speed |

800m/min |

The

3200mm/180 double-wire multi-cylinder long fourdrinier net A4 papermachine designed and manufactured

by our company can meet the industrial standard requirements, the agreement

requirements and quality standards reached by both parties, as well as the

particularly important process indicators.

The

equipment configuration of the machine can reach the predetermined production

capacity, and the paper machine's internal and external performance

requirements are taken into consideration.

The machine is entirely designed, manufactured, new, reliable, and never used as an advanced whole equipment.

Paper machine technological process

Open head-box → wire section (wire length 14m) → 4rollers with 2 press zones and 1 set large roller presses→14 φ1500 dryers →Sizing machine (φ600/φ605)→8 φ1500 dryers→calender →horizontal reel machine→Rewinder

Head-box: 1 set

The headbox is an air-cushion headbox, which is made of stainless steel square cone tube, plexiglass three-stage step diffuser, and the box is welded with steel plate and lined with stainless steel. Two stainless steel homogenizing rollers, the upper and lower lip plates are made of stainless steel, and the upper lip plate can be adjusted for full width and local adjustment. The pitch of the fine adjustment device is 120mm. The headbox has horizontal adjustment and lip adjustment and fine adjustment function. It has a headbox control system that can be connected with the DCS system signal to realize program logic control. The suitable range of sizing amount is 1:2, and the plexiglass observation hole is arranged on the box to facilitate the observation of the height of the pulp.

Wire section

The wire section consists of wire frame, a chest roller and a landing gear, a dewatering component group, guide mesh roller, a scraper, a high/low pressure water spray pipe, sprinkler, a tensioner, a corrector, a clear water tray, and a drive mesh roller, vacuum roll, fixed side water needle, cutter squirt, walking stand and so on. It uses a cantilever type change felt.

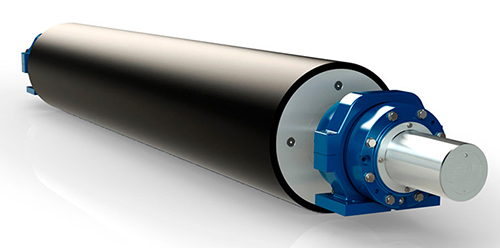

The department consists of 4 rollers with two press zones and 1 set large diameter rollers. The press section is equipped with a guide roller, a corrector, a tensioner, a high and low pressure water spray pipe, a suction box, a scraper, a water receiving tray, a walking platform and a roll changing trolley. The press section roller bearings are grease lubricated.

Drying section

18 sets φ1500mm drying cylinders (where 1#, 2#, 13#, 14# chrome surfaces are chrome-plated), the surface hardness of the drying cylinder is uniform, and the unprocessed surface is smooth and tidy.

Inclined sizing machine:1

set

three-roller calender:1

set

Paper wending machine:1

set

Rewinding machine

Scanning rack and infrared scanner:

1 set

Transmission Section

Basic Section

The long wire

section, the sizing machine, the calender, and the reeling machine are double

T-shaped groove ground rails, the press section, and the drying section is a

three-square groove ground rail. Equipped with anchor bolts, inclined irons,

etc., all the transmission ground rails and anchor bolts of the transmission

part are arranged. The base plate material is HT200, and all the base plates of

the machine are subjected to two heat treatments to ensure the straightness of

the base plate and no internal stress deformation.

Air compression system

The system

provides compressed air of suitable pressure and quality for each gas unit of

the paper machine. The gas source is provided by the user, and the gas source

is required to be clean, pure, degreased, dehydrated, and the air pressure

requirement is maintained between 6-8 kg/cm2. . The compressed air system

consists of a console, a gas control box, and field control components and

piping. Pneumatic control, pneumatic part of the valve and other control

components are installed inside the console, commonly used regulating valves,

pressure gauges, etc. are mounted on the console panel for easy operation. The

gas control box mainly supplies air to the actuator for the pneumatic tire and

the cylinder, and is installed nearby. Other control components are mounted on

the field pipe.

2BEC Water ring vacuum pump

water-steam separator