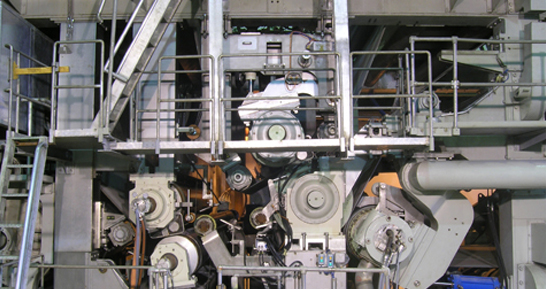

COMPLETE LINES

2 - DEFINITION OF A COMPLETE LINE

With its experienced engineering, process engineering and automation teams, Paperlink defines and calculates the dimensions of entire production lines; from the stock preparation to the winder, with the machine and its auxiliary equipment.

Paperlink provides a tailor-made solution for each customer, even for the most challenging projects.