Brief Description

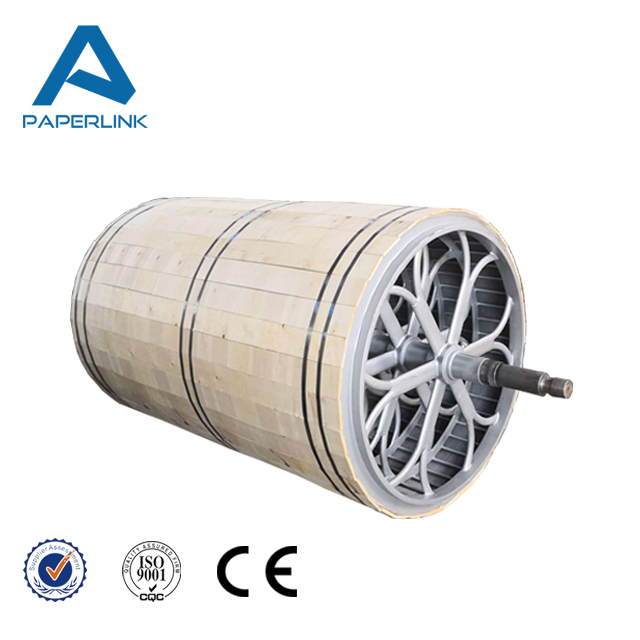

Paper Making Machine Parts Cylinder Mould SS Material Diameter 1.5m High Performance

Stainless Steel Cylinder Mould diameter 1.5m, Paper Making Machine

Cylinder mould model: Diameter 1250mm/1500mm/ 1800mm/2000mm×3600mm stainless steel cylinder mould.

Material

1. Main shaft: adopt 299mm×25mm seamless steel tube, 297×23mm after finished. When the pressure is ten tons, deflection is 0.00000000255m, which can be ignored. Shaft head structure is for 45# carbon steel

2. Spoke: Its material is cast iron. Quantity for inside and outside spoke is 19 pieces. It is with beautiful well-designed and smooth appearance, and without pulp attached. It is by natural aging treatment in order to keep the cylinder mould in shape.

Main parameters

Suitable Paper grade: Kraft liner paper, test liner board, corrugated paper and white board paper etc.

Single wire basic weight: 30-120g/m2.

Sizing concentration :0.3-0.8%.

Adaptable working speed: 70-180m/min.

Technical Parameters

| Main technical parameters | |

| Diameter | 1500mm |

| Diameter of SS stick | 12mm |

| Face length | 2000mm |

| Qty of SS stick | 80 |

| Qty of middle supportchip | 14 pcs |

| Thickness of SS strip | 15mm |

| Diameter of axis | 180mm |

| Stainless steel winding scrip | δ= 1.5 ×25mm |

| Dimension | 1.6mx1.6mx2.4m |

Main Features

1. Increase the area and the rate of water filtration, increase production

2. Improve the quality of paper, including the degree of uniformity, weight, aspect ratio

3. Reduce the copper net, cloth etc. consumption and maintenance cost

4. To strengthen the integrity of the equipment and anti-corrosion performance, durable Three has been developed and produced with a wear film, around the chip and the of oblique chip network.