Main Specifications:

|

LCD |

MOTOR RPM = 980 |

LCD |

MOTOR RPM = 980 |

|||

|

CAPACITY (M3) |

TPD |

POWER (Kw) |

CAPACITY (M3) |

TPD |

POWER (Kw) |

|

|

6 |

25-30 |

75 |

26 |

200-250 |

250 |

|

|

8 |

40-45 |

90 |

32 |

250-300 |

315 |

|

|

10 |

70-75 |

110 |

35 |

300-330 |

355 |

|

|

12 |

70-90 |

132 |

40 |

350-400 |

400 |

|

|

16 |

110-120 |

150 |

50 |

400-450 |

450 |

|

|

18 |

120-140 |

180 |

60 |

450-500 |

550 |

|

|

20 |

140-150 |

200 |

70 |

600-650 |

600 |

|

|

22 |

150-160 |

220 |

||||

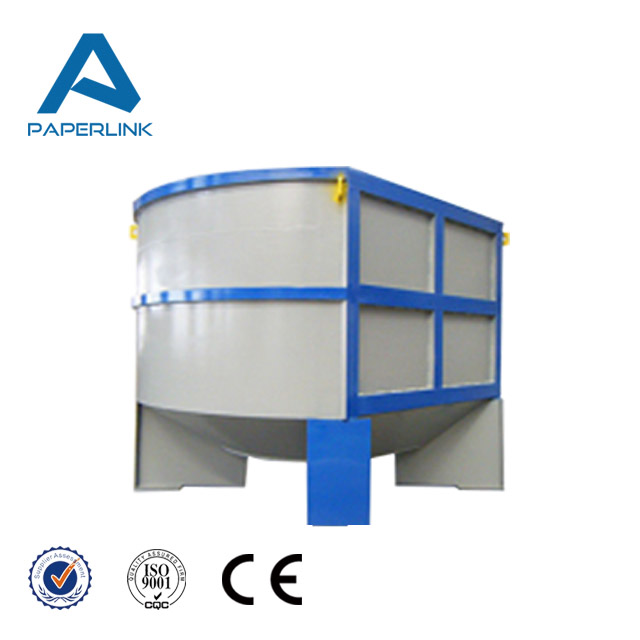

Application & Salient Feature

‘D’ Section of the tub increases

the turbulence in the Tub causing bales/bundles to submerge rapidly and thus,

reduce the dwelling time

Suitable for continuous operation.

Suitable for furnish of OCC, AOCC, Box Board separate the reject and fiber. The

Fiber discharge line is connected to the pulp suction or directly fed to

storage towers.

Breif Description

Pulping Equipment Disc Deflaker consists of the pulping room,a transmission struction,a base,motors and so on.pulping room is fixed on the casing and the movable seat on two fixed disk and mounted on a rotating disk of the two rotating disc,forming two pulping zone.Through replacing different tooth grinding,to meet the various requirements of striking pulp.

This double disc refiner is used for continus ous refining kinds of paper pulp,and straw ,wood , reed ,bamboo,rag and waste paper pulp.This machine is a pulping machine of coarse and correct gringding in papermaking and wastesd paper remaking thick liquid. It has the advantage of high poroduction efficency and low power consumption.

The Advantages Are

- The

model ‘D’ refers to the shape of Tub.

- Continuous

Operation

- Operating

consistency 4-6%

- Higher

capacity (TPD) with reduced power input compared to normal vertical Pulper

- S.S.

Cast Roter of special design for handling different grade of low matrial

- ‘D’

Pulper can operated in ambient temp . as well as elevated temp. Upto 700C.

- Heavy

duty sturdy bearings take impact load of bales/waste paper bundles.

- Removes

Plastic in large pieces with little degradation.

- Reduce

burden on downstream equipment.

- Decreases/eliminates

clean out down time.

- External adjustment of rotor to maintain clearance between rotor and screen

Service

We strictly in accordance with the production system, never let defective or substandard products affected parts of the product; Due to mechanical products from a variety of bulky component parts, and therefore the need for strict to grasp the scale of the operation of the machine to be good, to ensure the life of the machine, increase the production capacity of the machine products.

After-sales service commitment, preferential commitment and quality assurance plan

1. Training users can independently operate, use and maintain, such as equipment operation technology, maintenance technology

2. Answer technical questions in a timely manner. If the user cannot solve the technical problem, our company will promptly send people to the user site to assist in guiding.

3. If the user needs to update the equipment or expand the construction project, we will provide free technical guidance.