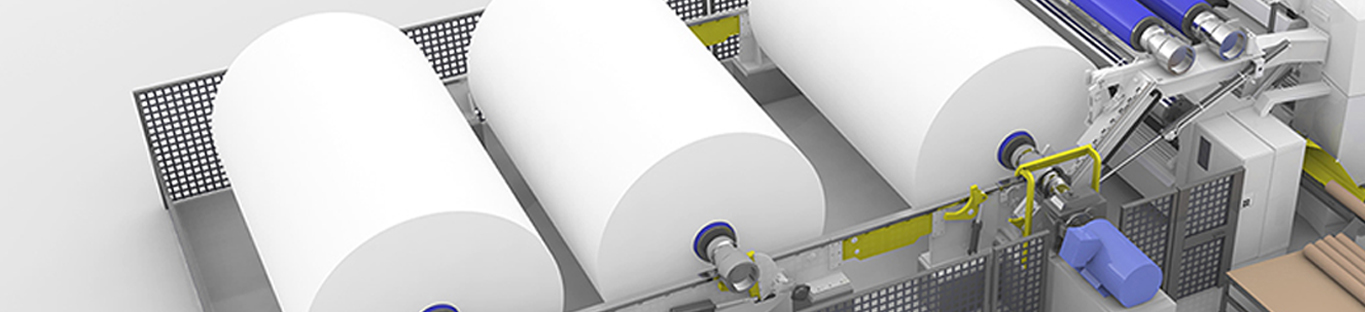

Paperlink Group has developed a comprehensive portfolio covering all stages of the production of paper, board, wet line nonwoven and composite productions. The company's agility combined with its process and mechanical expertise enables it to provide tailor-made solutions suited to each customer's needs and ambitions. Customized solutions are the key to success.

As a full-line supplier for packaging paper machines, we also focus on efficient and resource-conserving solutions. By working closely with our customers, we repeatedly achieve breakthroughs in machine speed and arammage. For our customers, this has a clear economic beneft, as more.goods can be produced in a shorter time.

Specifation

|

Applicable Industries |

Manufacturing

Plant, Machinery Repair Shops

|

Local Service Location |

India, Russia,

Morocco, Bangladesh, South Africa, Kazakhstan |

|

Showroom

Location |

Egypt, Turkey,

India, Russia, Bangladesh, Uzbekistan |

Condition |

New |

|

Product Type |

toilet tissue

paper making machine line |

Processing

Type |

toilet paper

production line |

|

Place of

Origin |

Henan, China |

Brand Name |

PAPERLINK |

|

Voltage |

220V |

power(W) |

380KW |

|

Dimmension (L*W*H) |

80*25*30 |

Weight |

90T |

|

Certification |

ISO9001 |

Warranty |

1 YEAR |

|

After-sales

Service Provided |

Free spare

parts, Video technical support, Field installation |

Production

Capacity |

98.6% |

|

Machinery Test

Report |

Provided |

Video

outgoing-inspection |

Provided |

|

Machinery Test

Report |

Provided |

Video

outgoing-inspection |

Provided |

|

Marketing Type |

New Product

2020 |

Warranty of

core components |

1 YEAR |

|

Core

Components |

PLC, kraft

paper machine manufacturers |

Output paper |

toilet tissue

paper |

|

Net paper

width |

787-3600mm |

Paper roll

width |

787-3600mm |

|

GSM |

13-40g |

Headbox lip

width |

3600mm |

|

Design speed |

100-500m/min |

Capacity |

10-40T/D |

Production Description

We can design the factory according to the customer's requirement. Customers can use the original paddle board, sugarcane waste or waste paper, or they can decide the final production's quality which they intend to produce. We provide complete production line of toilet paper roll, which can produce the following kinds of paper.

1.Toilet paper 2. Napkin 3. Facial tissue 4. Hand paper

The paper production line is made up of seven main parts

1.stock preparation system(pulping section)

2.wire section manufacture of paper mills in chain

3.Vacuum press section kraft paper machinery

4.Ordinary press section

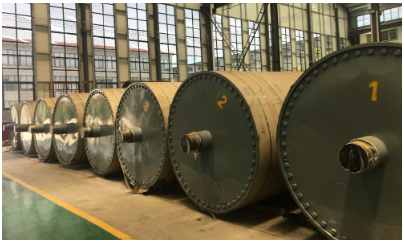

5.drying section Corrugated paper machine

6.paper winding section

7.finished paper section

Machinery Structure

Pulping system Wire Section

Drying Section

Packing&Deliver

The normal package is wooden box(Size :L*W*H).

We can also pack it according customers special request.

For paper machine project, selecting a high-quality equipment is just the first step to success. Our professional team not only provides fine equipment, we provide various and rounded services. It covers workshop design consulting, warehouse logistic management, recipe management operation and maintenance training etc. We have our own international talent pool.

We are ready to at your proposal. We do turn-key project.