Fourdrinier Type kraft liner Paper Machine

This technical proposal is oriented to the complete system of paper machine in the project of 3600mm Double headboxs multi-cylinder paper machine. It accurately, clearly and completely describes the technical requirements of users in the paper machine system, and gives the technical program of the project so that our company and your company can discuss and exchange technology.

This machine is used to 70-200g/m2 Kraft liner machine. It is composed of long web forming part, press part, dry cadre, roll paper part, transmission part, base part, hood part and so on.

Fourdrinier | Wire section adopts wire forming, choose Air cushion type head-box feed pulp. |

Pressure section | Pressure section made of K-Type pressure and 1 set large diameter rollers. |

Drying section | Drying section adopts 32 sets φ1800mm cylinder dryers,The grouping arrangement is as follows:(20+sizing machine+12) |

Paper winding section | paper winding section adopts horizontal pneumatic cylinder rewinding machine. |

Transmission section | The transmission section adopts segment transmission and AC frequency conversion speed control. |

Equipments

Headbox: Quality:2 sets; Type: Air cushion type headbox ; Overflow Quantity : 2~5%

Wire section:

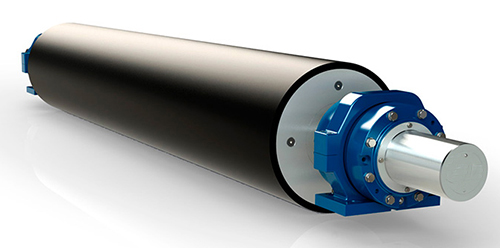

1 Chest roller and landing gear: 2 sets; Chest roller; Quantity: 2 sets; Specification : φ600mm×4050mm×4700mm

2. Drive felt roller: Quantity: 1 sets; Specification: φ600mm×4050mm×4700mm

3. Return roller: Quantity: 1 set ; Specification : φ600mm×4050mm×4700mm

4. Compound roll: Quantity: 1 set: Specification : φ800mm×4050mm×4700mm

5. Vacuum couch roller: Quantity: 1 set; Specification: φ800mm

6. Guide roller: Quantity: as design; Specification: φ260mm×4200mm×4700mm

7.Transmission guide roller: Quantity: 1 set; Specification: φ315mm×4050mm×4700mm

Forming board :Quantity: 2 sets;Specification: 630mm×4050mm×4700mm;Type: 1+4 pieces Type

Waste paper stirring device:

Combine roller landing gear quantity: 2 sets;Turbine:ZQSn6-6-8; Screw:Q235A;Connecting Rod:Q235A

Pressure section:

The department consists of 2 sets large diameter rollers. Total 2 press zones. The press section is equipped with a guide roller, a corrector, a tensioner, a high and low pressure water spray pipe, a suction box, a scraper, a water receiving tray, a walking platform and a roll changing trolley. The press section roller bearings are grease lubricated.

1.Large roller press blind hole roller: Quantity: 4 sets; Specification:

φ1250mm×4050×4700mm;Roller material: HT300; spindle head: ZG45

2.Guide roller: According to the designed quantity; Specification: φ260mm×4050mm×4700mm; Roller body: Roller body is made of 14mm carbon steel pipe, Roll surface chromium plating 0.05mm, cast iron boring head heat sleeve 45# round steel at both ends, roller finishing Dynamic balance.

3.Cleaning reel: Quantity:2 set; Specification:φ245mm×4200mm×4700mm; Roller body: Roller body is made of 14mm carbon steel pipe, Roll surface chromium plating 0.05mm, cast iron boring head heat sleeve 45# round steel at both ends, roller finishing Dynamic balance.

4.Stretch roller: Quantity: 4 sets; Specification: φ270×4200mm×4700mm; Roller material: Q235A steel pipe

Drying section:

Finished paper dryness: 92%

Maximum use steam pressure: 0.3MPa

Hydraulic test pressure: 0.6MPa

Drying cylinder balance: G4

Guide roller, paper roller dynamic balance: G2.5

Dry mesh tension: 4KN/M

The transmission form is: Air cushion type gear transmission